Industrial Vacuum Manufacturers: Revolutionizing Industry Standards

The industrial vacuum cleaner is an essential tool across many sectors, from manufacturing to food processing. Industrial vacuum manufacturers provide high-efficiency solutions tailored to meet the rigorous demands of various industries. This article delves deep into the world of industrial vacuum manufacturing, focusing on advancements, benefits, and how these innovations contribute to operational efficiency.

Understanding Industrial Vacuum Cleaners

Industrial vacuum cleaners are specialized devices designed to handle large quantities of debris and contaminants. Unlike traditional models used in homes or small offices, industrial vacuums are built to withstand heavy-duty applications, delivering superior suction power, durability, and advanced filtration systems.

Key Features of Industrial Vacuums

When evaluating industrial vacuum manufacturers, it is essential to understand the key features that set these machines apart from conventional vacuums:

- High Suction Power: Designed to tackle the toughest cleaning tasks.

- Robust Construction: Made from durable materials to ensure longevity in harsh environments.

- Advanced Filtration Systems: Capable of capturing fine dust particles and hazardous contaminants.

- Scalability: Available in various sizes and configurations for different industry needs.

- Energy Efficiency: Many models focus on reducing energy consumption while maximizing performance.

The Importance of Selecting the Right Manufacturer

Choosing the right industrial vacuum manufacturer can significantly impact productivity and safety in the workplace. A reputable manufacturer will offer:

- Customization: Tailored solutions that fit specific industry requirements.

- Reliability: Consistent performance to ensure minimal downtime during operations.

- Technical Support: Ongoing support and maintenance services to keep equipment operating efficiently.

- Innovation: A commitment to developing cutting-edge technology and staying ahead of industry trends.

Impact on Various Industries

Industrial vacuum manufacturers cater to a wide array of sectors, each with unique cleaning challenges:

Manufacturing

In the manufacturing sector, industrial vacuums are vital for maintaining cleanliness on production lines, reducing contamination risks, and ensuring employee safety. These vacuums efficiently remove metal shavings, plastic fragments, and other debris that accumulate during production.

Food Processing

The food processing industry demands stringent hygiene standards. Industrial vacuum manufacturers produce specialized vacuums that comply with health regulations, ensuring the removal of residues without contaminating food products. This minimizes the risk of foodborne illnesses.

Construction and Renovation

On construction sites, the presence of dust and debris is unavoidable. Industrial vacuums play a crucial role in keeping these environments clean, providing a safer working atmosphere and aiding in compliance with health and safety regulations.

Technological Innovations in Industrial Vacuum Manufacturing

The realm of industrial vacuum manufacturers is constantly evolving, with technology pushing boundaries further than ever before. Here are some key innovations currently shaping the industry:

Smart Technology Integration

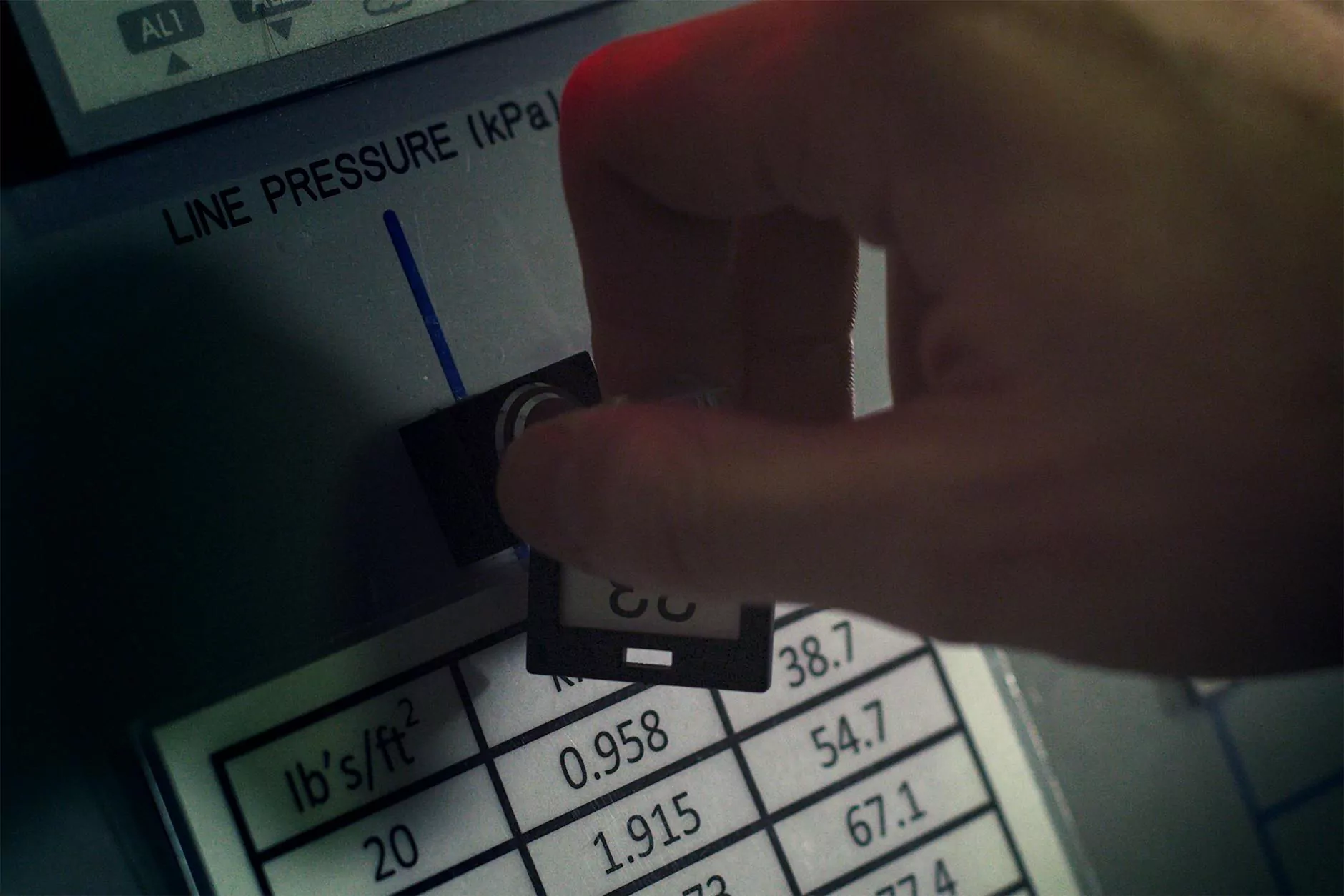

Modern industrial vacuums incorporate smart technologies that allow for remote monitoring and control. This connectivity ensures machines can be managed more efficiently, diagnosing issues before they lead to failure.

Improved Filtration Systems

Recent advancements in filtration technology have led to the development of HEPA filters that capture 99.97% of particles, ensuring a clean environment. These filters are now a standard feature in many of the latest models from leading industrial vacuum manufacturers.

Eco-Friendly Designs

With an increase in environmental awareness, many manufacturers emphasize eco-friendly designs that reduce energy consumption. Innovations include efficient motor technology and recyclable materials, helping companies minimize their carbon footprint.

Choosing the Right Model for Your Needs

When selecting an industrial vacuum, consider the following factors:

Application Type

Different applications may require different types of vacuums. Assess whether you need a wet/dry vacuum or one specifically designed for hazardous materials. Understanding your specific requirements will guide you in selecting a model that meets your needs.

Capacity and Size

The size of the vacuum should align with the volume of debris typically encountered in your operations. Larger models are suited for extensive operations, while compact units may be ideal for smaller spaces.

Mobility

Many industrial vacuum manufacturers offer portable models that facilitate ease of movement across work sites. Wheels and handles can make a significant difference in productivity.

The Future of Industrial Vacuum Manufacturing

As industries continue to evolve, the future of industrial vacuum manufacturers appears bright. Trends influencing the market include:

Automation

With the rise of automation, smart vacuums equipped with AI can autonomously navigate workspaces, adapting to various cleaning challenges without human intervention.

Increased Focus on Health and Safety

As workplace safety becomes a priority, the demand for efficient cleaning solutions, such as industrial vacuums, is rising. Manufacturers that prioritize safety innovations will likely lead the industry.

Conclusion

In conclusion, industrial vacuum manufacturers play a pivotal role in enhancing operational efficiency across various industries. By understanding their products and the advancements in design and technology, businesses can select the right vacuum solutions that meet their specific needs. With ongoing innovations, the future of industrial vacuums is set to redefine industry standards, making workplaces cleaner, safer, and more efficient.